Multistage Pumps

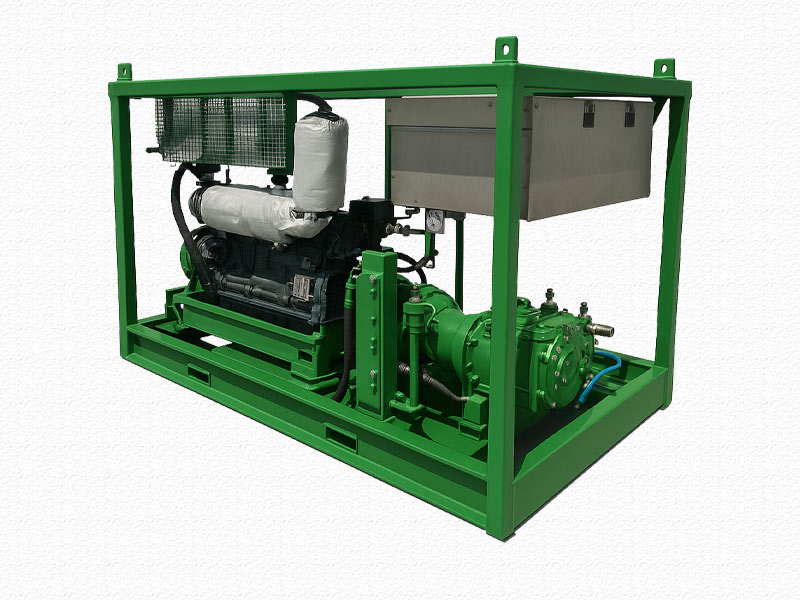

The High Pressure Multistage Pumps are robust and efficient systems designed for critical pipeline operations such as flooding, pigging, testing, and flushing. With a flow capacity of up to 1000 m³/h and pressure handling up to 130 bar, these pumps are built to perform under extreme conditions. They are available in sizes ranging from 3 to 12 inches and offer a wide selection of materials to suit various industrial needs.

Featuring a self-priming setup, they eliminate the need for additional priming pumps, making them highly convenient for on-site use. The pumps also include a power take-off system, durable DNV-certified skid options, and the ability to achieve suction lifts up to six meters, ensuring both flexibility and reliability in demanding applications.

Annovi Pumps

Annovi pumps from Italy are high-performance solutions engineered for a wide range of industrial applications. These pumps can be powered by diesel engines, electric motors, hydraulic systems, or truck PTOs, providing great flexibility across different setups. With flow rates ranging from 2 to 400 LPM and pressure capabilities up to 1000 bar (14,500 PSI), they are built to deliver reliable and consistent performance even in the most demanding conditions.

Commonly used for hydrojetting, Hydrotesting underwater jetting, deck and tank cleaning, as well as surface preparation, Annovi pumps are trusted for their efficiency and durability. Key models include the Water Jetting Pump, offering up to 135 LPM at 1000 bar, and the High Flow Pump, capable of delivering 400 LPM @ 135 bar—making them ideal for both high-pressure and high-volume cleaning tasks.

Hydroblasting Pumps

Onshore and offshore applications for water jetting units and hydroblasting include ship blasting, condenser tube decking in refineries, cleaning crude oil tanks in tank farms, and underwater marine growth removal from heat exchangers.

Built to deliver pressures up to 40,000 PSI and flow rates up to 500 LPM, Hydroblasting Pumps are ideal for demanding industrial cleaning tasks. Their robust design and high-performance output make them suitable for mobile or stationary setups, ensuring effective and efficient cleaning in even the most challenging environments.

Hydrotesting Pumps

Hydrotesting Pumps are engineered to deliver pressures up to 40,000 PSI and flow rates up to 500 LPM, making them ideal for high-pressure testing applications. These systems are primarily used for cross-country pipeline testing, flushing operations, and evaluating the integrity of oilfield equipment including pipes, tanks, and pressure vessels.

Designed for precision and durability, hydro test pump packages ensure safe and accurate testing in critical infrastructure and energy sectors. With customizable configurations available, they offer flexibility to suit specific project requirements and challenging operational environments.

Multistage Centrifugal Pumps

Multistage Centrifugal Pumps are designed to deliver high-pressure performance through multiple impellers (stages) arranged in series, making them ideal for applications requiring consistent pressure and flow. These pumps are commonly used in boiler feed systems, high-pressure cleaning, water supply and distribution, and pressure boosting in industrial plants.

Engineered for efficiency and reliability, multistage pumps handle a wide range of liquids with varying viscosities and temperatures. Their robust design ensures minimal maintenance, while their compact structure allows easy integration into existing systems. Custom-built options are also available to meet specific operational needs.

Endsuction/ Chemical Cleaning Pumps

End Suction / Chemical Cleaning Pumps are specifically engineered for efficient cleaning of pipes and vessels using high-flow chemical solutions. These pumps provide a robust solution for system flushing and industrial cleaning tasks where reliability and consistent performance are essential.

With a flow capacity of up to 600 m³/h and a head pressure of up to 16 bar, these pumps are driven by either electric motors or diesel engines. They are built with end suction centrifugal configurations and offered in a range of materials tailored to handle different chemical compositions. Their compact, customizable design makes them ideal for integration into diverse industrial environments.

Accessories

Our Water Jetting Accessories are engineered to deliver precise control, safety, and efficiency in high-pressure cleaning and cutting applications. The range includes dump guns, shut-off guns, and zero-thrust guns for controlled fluid release, as well as foot-control valves for hands-free operation. These tools ensure smooth, responsive handling, especially during maintenance and underwater tasks.

Supporting components like high-pressure hoses, nozzles (fan, straight, rotating, and directional), flexible and rigid lances, rupture discs, and pressure sensors ensure effective flow, safety, and system monitoring. Paired with essential PPE and safety gear, this complete accessory set provides a reliable and safe solution for industrial water jetting needs.

UHP Hydroblasting Pump

Ultra High-Pressure (UHP) Hydroblasting Pumps are engineered for demanding industrial cleaning tasks, delivering pressures up to 40,000 PSI for the efficient removal of tough coatings, scale, and deposits. These pumps are ideal for surface preparation, heat exchanger cleaning, tank and vessel maintenance, and other high-performance applications where conventional methods fall short.

Built for reliability and performance, UHP pumps are driven by robust diesel or electric motors, and are compatible with a wide range of nozzles and accessories. Their precise control and high-impact waterjetting capability make them a preferred choice in petrochemical plants, refineries, shipyards, and heavy industries.